XTIOT Tobacco and Alcohol Traceability Data Matrix Barcode Scanner

As a high-tech enterprise specializing in the design, development and production of automatic identification products, XTIOT provides a series of Data Matrix barcode scanners suitable for tobacco and alcohol traceability. For the XTIOT Tobacco and Alcohol Traceability Data Matrix Barcode Scanner, the following is a detailed analysis of product features, application scenarios, technical specifications and after-sales service:

1. Product Features

High-precision identification:

Designed specifically for Data Matrix barcodes, it can efficiently and accurately identify tiny, high-density Data Matrix barcodes on tobacco and alcohol products.

Supports the identification of complex barcodes such as color inversion, stains, and blurs to ensure the integrity of traceability information.

Flexible configuration:

Provides a variety of interface options (such as USB, RS232, TTL, etc.) for easy integration with different devices and systems.

Supports wireless connections (such as Bluetooth, Wi-Fi, etc.), suitable for various complex or mobile working environments.

Durable and reliable:

Adopts industrial-grade design, dustproof, waterproof, and shockproof to ensure stable operation in harsh environments.

Long-term trouble-free operation meets the high-intensity and high-frequency scanning needs of the tobacco and alcohol industry.

Data storage and transmission:

The internal storage function may be available to temporarily store scanned data for batch upload or offline operation.

Support real-time data transmission to ensure the immediacy and accuracy of traceability information.

2. Application scenarios

Tobacco and alcohol production:

Barcode scanning of packaged tobacco and alcohol products on the production line to record production batch, production date and other information.

Logistics and transportation:

During transportation, logistics information such as transportation time and location are recorded by scanning barcodes.

Sales and traceability:

At the point of sale, consumers or sales staff can obtain detailed information on tobacco and alcohol products by scanning barcodes to achieve anti-counterfeiting verification and traceability query.

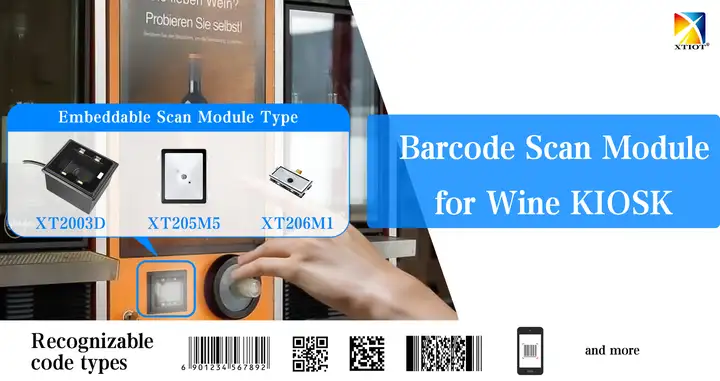

3. Technical specifications (taking XT2003D, XT3001AHD, XT6203 models as examples)

Interface type:

USB, RS232, TTL, etc.

Scanning rate:

Depends on the specific model, generally up to hundreds of times/second

Scanning distance:

0-750px (depends on the model and barcode density)

Resolution:

High-resolution CMOS to ensure clear recognition of barcodes

Error correction capability:

Built-in powerful error correction algorithm, supports recognition of damaged and contaminated barcodes